SB-7705 series is the unique to defuse 3D(X,Y,Z) vibrations by “Multi-speed Multi-plane Balancing Algorithm” for preventing vibration at wide speed range of flexible rotor with higher order of bending modes.

•Rechargeable battery model is available.

•Variable-speed Spindle of Machining Center, Textile and spinning machines, Tapping center, etc.

•NC Lathe, High-speed Die Machinery, High-speed Slicer, Dicing Saw, Internal Grinder, Woodworking Machinery, Crusher, Blower, Pump, Compressor, etc.

•Most of precision grinder as Surface grinder, Forming grinder, Centerless grinder, Cylindrical grinder (-optional)

Features

For balancing of flexible and rigid rotors.

•As increasing rotational speed and downsizing of machinery, relative stiffness becomes lower and lower. It causes critical speed will exist in operating speed range.

•Multi-speed multi-plane balancing method provides to defuse vibration at all operational rotating speed range.

Conventional constant speed balancing function is available.

High accuracy and efficient balancing 1 to 4 plane balancing

•Resolution of 0.001μm at up to 240,000min–1 (SB-7705RS)

•Low speed balancing down to 60min-1model is available (SB-7705RL)

•Measuring response is 2x fast by 2channel simultaneous measurement. (Compared to Sigma’s products)

After balancing vibration forecasting function

High efficiency balancing can be performed by after balancing vibration forecasting function.

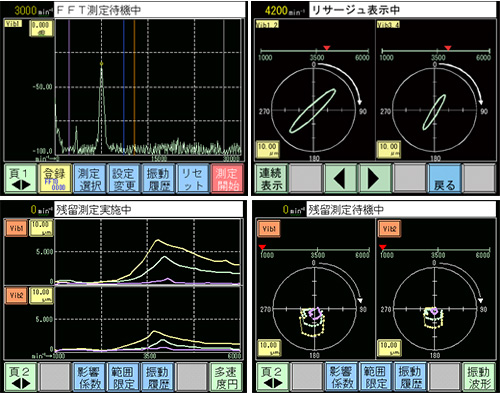

FFT analyzer is equipped as standard

Frequency analysis and diagnostic of rolling bearing are included.

Vibration analysis functions

•Unbalance vibration monitoring

•Harmonic analysis

•Overall amplitude monitoring

Lissajous display function

•Lissajous at each rotational speed can be displayed continuously.

•Locus of shaft center can be observed easily.

Documentation and archiving

With our utility software, the measurement results can now be transferred directly onto your PC as CSV files and MS-Excel reports.

•Measurement data can be stored in USB memory.

•Measurement data can be printed out with mechanical dot printer. (-optional)

•Screenshots can be stored in microSD memory or transferred to PC.

Touch screen color LCD

•Easy operation with 5.7" graphical color display

•User-friendly procedure and help function

Unbalance correction by balance weights arrangement -optional

•Unbalance can be corrected by arranging 2 or 3 balance weights on the circumference. This method is popular for balancing of grinding wheels.

•If this method is applied to general industrial machinery, balance correction will be easily done only by rearrangement of balance weights, weight selection and/or fabrication is not needed.

•SB-7705 series can be applied 1 plane(G) or 2 plane(GW) balancing.

Options

•Unbalance correction by balance weights arrangement

•Vibration Channel

•Vibration Sensor for multi-plane measurement

FFT analyzer, Lissajous display function

Wave form/ Modal circle of Multi-speed

Selectable Measuring Channel (4ch/6ch)

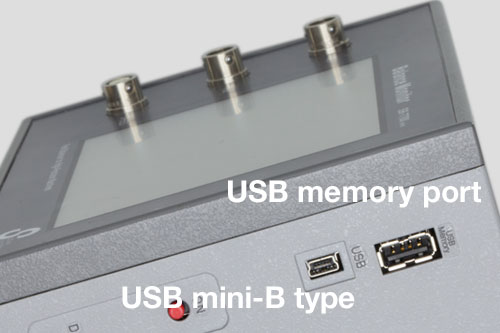

•USB mini-B connector

•USB memory port

Instrument and all accessories are stored in an attaché case

Weight: 8kg

Operating Flowchart

SB-7705R Specifications

| 【Measurable rotaion speed:Normal】 【Measurable rotaion speed:High speed】 【Measurable rotaion speed:Super high speed】 【Measurable rotaion speed:Low speed】 | |

|---|---|

| Model | SB-7705RRHRSRL- |

| 【Measuring range】 | |

| Applicable Rotors | Rigid Rotor, Flexible rotor, Grinding wheel |

| Balancing Speed(Fixed-speed) | 180min–1 to 61,000min–1 180min–1 to 120,000min–1 180min–1 to 240,000min–1 60min–1 to 61,000min–1 |

| Balancing Speed(Multi-speed) | 600min–1 to 61,000min–1 600min–1 to 120,000min–1 600min–1 to 240,000min–1 |

| Resolution of rotational speed display | 1 min–1 |

| Resolution of vibration | 0.001µm |

| Vibration input channel | 4ch / 6ch |

| Measuring method | Multi-speed measurement, Fixed-speed measurement |

| Number of Correction plane | 1 to 4 (Multi-speed), 1 to 2 (Fixed-speed) |

| 【Correction method】 | |

| Polar coordinates | 0° to 359° (angle resolution:1°) |

| Components of unbalance vector | 3 to 50 |

| Correction weight | Add / Remove |

| 【Vibration analysis function】 | |

| Unbalance Vibration Analysis | Time-series record of unbalanced vibration vectors |

| Harmonic Vibration Analysis | Analysis of harmonic components |

| FFT Analyzer | Frequency analysis function (Includes time waveform measurement function) |

| OverAll Vibrometer | Acc. Peak / Acc. RMS / Acc. C.F. / Vel. RMS / Disp. EQP (Meas. range Acc:0.1 to 40m/s²) |

| OverAll Vibration monitor | Not equipped |

| 【Others】 | |

| USB memory port | Standard equipped |

| USB communication port | mini-B (Data transfer to PC, Hard copy of screen) |

| Eccentricity correction function | Standard equipped |

| Measurement range switching | Automatic |

| Number of registered data stored | 8 (4 for 6-channel specifications) 4 (2 for 6-channel specifications) |

| Display | 5.7 inch TFT color LCD (LED back light method) / Touch panel |

| Power supply | AC drive AC adapter:AC100 to 240V ±10% 50/60Hz |

| Environmental | Temperature:10 to 40℃・Humidity:20 to 80%RH (Non-condensing) |

| Dimensions of measuring unit | 204(W) × 71(D) × 137(H) mm |

| Mass of measuring unit | Approx. 1.7kg |

| Dimensions of storage trunk case | 455(W) × 185(D) × 320(H) mm |

| Total mass (Includes accessories) | Approx. 8.0kg |

| 【Accessories】 | |

| Vibration sensor |

P12SC Sensitivity:10pC/(m/s²) Fix magnet:KM-025C (Adsorption:100N) Cable:LN-041-025 (2.5m straight) |

| Low-speed Displacement Sensor |

V10L Sensitivity:0.5mV/µm Fix magnet:MB-B (Adsorption:800N) Cable:Low-speed Displacement Sensor Cable (2.5m) Note:Low-speed Displacement Sensor (type V10L) can be used only for low speed balancing. The sensors cannot be used for general vibration measurement purpose other than balancing. |

| Rotation sensor |

SFS-N41 (2.0m cable assembled) Fix magnet:DG1030 (Adsorption:800N) Instruction manual included |

| AC adapter |

Japan:UN312-5920 (DC5.9V, 2A) Plug type:Type-A outside Japan:UI318-06 (DC6V, 2.8A) Plug type:Type-A (AC code conversion method*) *AC cords other than Type A must be provided by the customer. |

| Circular protractor | 822-0001 (ø15cm) |

| Manual | CD-ROM (Digest manual included) |

| 【Option】 | |

| Unbalance correction | Balance weights arrangement for grinding wheel (G:1-plane, GW:2-planes) |

| Number of vibration input channel | 4ch / 6ch |

| Additional sensor for multi-point measurement | Vibration sensor P12SC + Vibration sensor cable LN-041-025 |