Fully automatic Vertical 1-plane balancing machine

SHVA-6130A

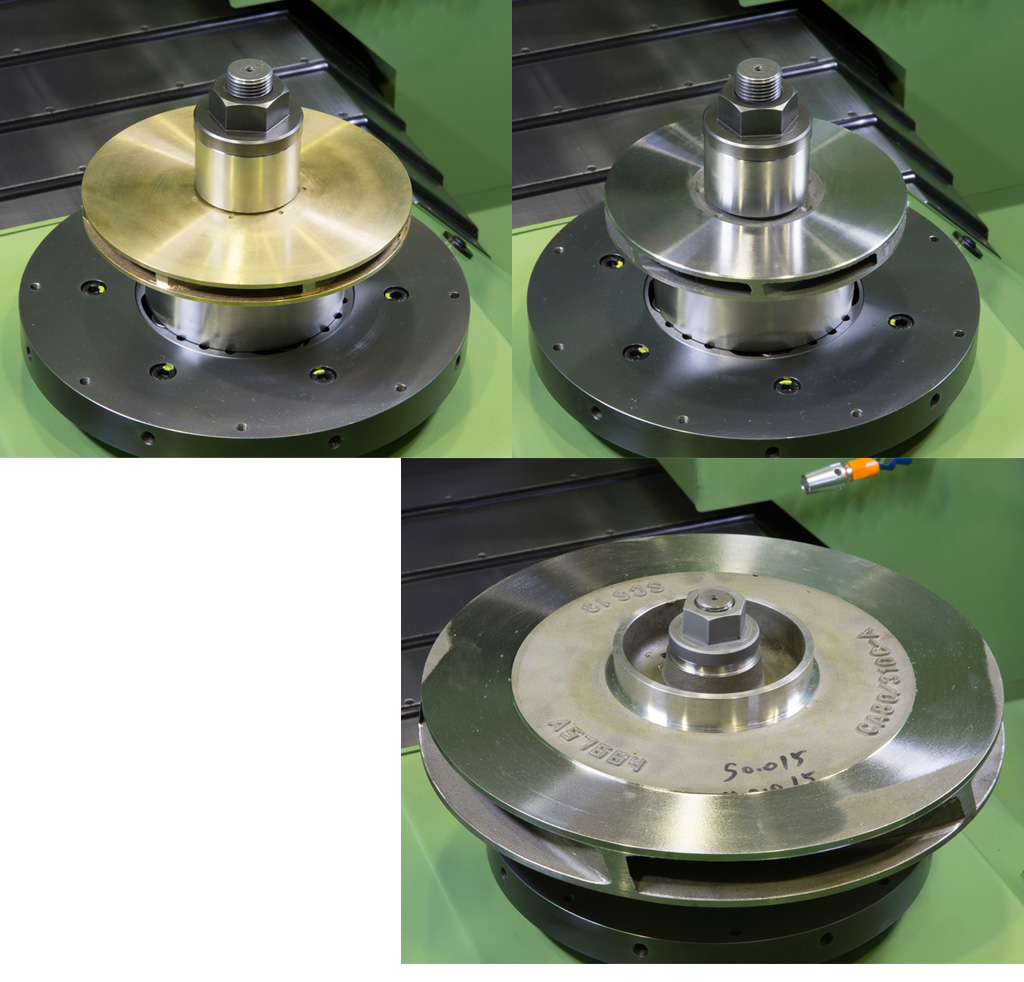

Fully automatic balancing machine for pump impellers has been released on 1994. Once workpiece is mounted on the machine, measurement and correction are performed at same arrangement. Correction of unbalance is performed by lathe-unit; therefore surface of the workpiece is smooth after unbalance correction.

- Balancing plane : 1 plane

- Workpiece Mass : 30kg max.

- Rotor dia.: ø600mm max.

- Chucking adapter : Manual fixing

- Balancing Speed : 800min-1

- Min. Achievable Unbalance :1.0 μm

Pump impeller, Flywheels, etc.

Features

- Fully automatic

- Unbalance correction by lathe-unit

- Built-in spindle motor

- Small foot print

Fully automatic operation from measurement to correction without set‐up change.

High-accuracy balancing because no cumulative error of reattaching.

High accuracy unbalance correction

No step after cutting, suitable for fluid machinery parts.

Steady measurement because there is no transmission component which is cause of disturbing vibration.

Specifications: SHVA-6130A

| Model | SHVA-6130A | |

|---|---|---|

| Workpiece | Max. Mass | 30kg |

| Max. diameter | ø600mm | |

| Max. surface waviness | less than 1mm | |

| Mechanical unit | Chucking adapter | Manual fixing or pneumatic operated diaphragm chuck |

| Balancing speed | 800min-1 | |

| Bearing support system | Hard type | |

| Measuring unit | Balancing plane | 1 plane |

| Min. Achievable Unbalance | 1.0µm | |

| Tact time | 58sec. at 115 g-cm initial unbalance | |

| Graphic display | 10.4" TFT color LCD with touch screen | |

| No. of stored work data | 100 data (No limitation when use with USB memory) | |

| Others | Power supply | 3 phase 200V ±10% |

| Pneumatic supply requirement | 0.5MPa | |

| Option | Tip conveyer | |

| Dimensions | 1,200(W) × 1,600(L) × 1,770(H)mm (without tip conveyer) | |

| Mass | Approx. 2,500kg | |