Balancing and Evaluating system for high-precision spindle

SSB-5850A

High efficiency balancing of assembled rotors

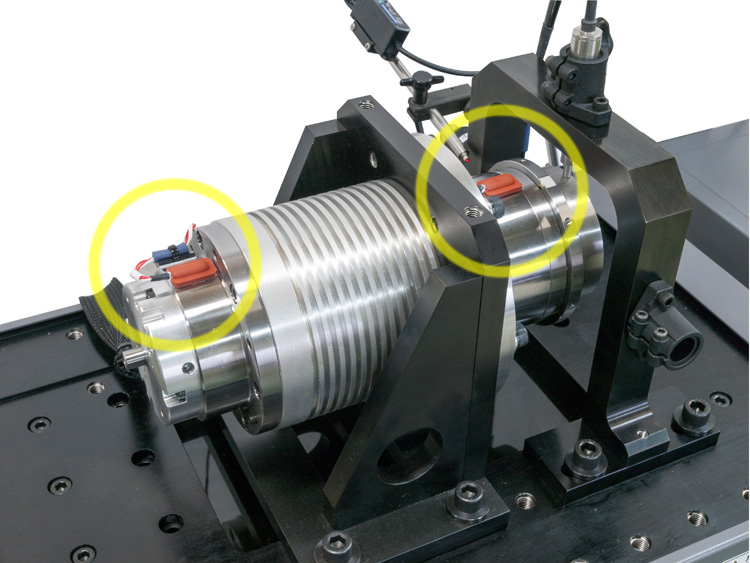

- Measured object : Self-driven high-precision spindle

- Maximum rotor mass : 50kg

- Minimum achievable residual unbalance : Depend on bearing of work

- Number of correcting plane : 1 or 2

- Dimension of work pedestal : As customer’s request

- Measuring rotational speed : 180 to 120000min-1

- Measuring method : Multi-speed or Fixed speed, selectable

- Monitoring items : Vibration, temperature including FFT, bearing diagnostic function

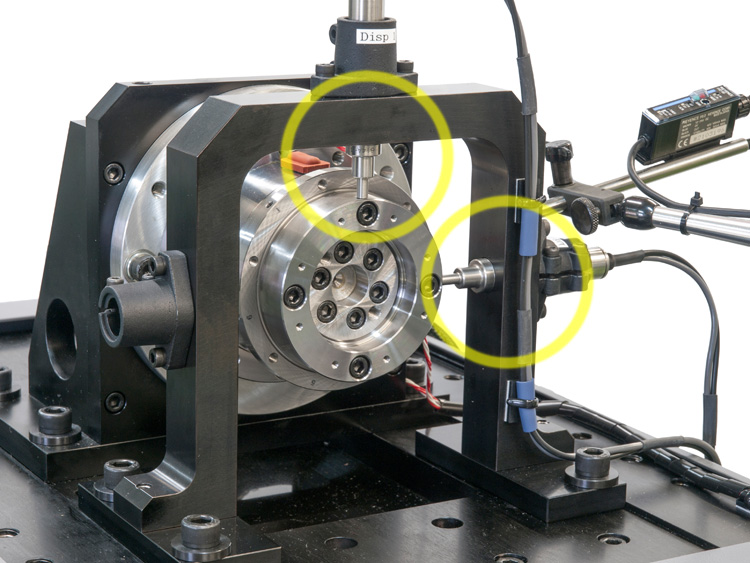

- Optional : Dynamic response evaluation with non-contact displacement sensor

Spindle assemblies, Motor assemblies, Turbo charger assemblies, etc.

Dynamic response evaluation with non-contact displacement sensor

Monitoring temperature with PT100

Features

- For complicated rotors

- Monitoring items

- Touch screen operation

- Small foot print

Complicated shape rotors can be precisely balanced by dedicated fixtures.

Vibration, temperature including FFT, bearing diagnostic function

Specifications: SSB-5850A

| Model | SSB-5850A | |

|---|---|---|

| Workpiece | Max. Mass | 50kg |

| Drive system | Self drive | |

| Mechanical unit | Balancing speed | 180 to 120,000min-1 |

| Bearing support system | Soft type (cradle type) | |

| Measuring unit | Min. Achievable Unbalance | Depend on bearing of work |

| Balancing plane | 1 and 2 | |

| Graphic display | 5.7" TFT color LCD with touch screen | |

| Min. unbalance indication | 0.001mg | |

| Unbalance measuring mod | Multi-speed multi-plane, Fixed-speed multi-plane | |

| Monitoring items | Vibration, temperature | |

| bearing diagnostic function | Including FFT | |

| Indication mode | Polar coordinates and (3 to 99) components of unbalance vector (add or remove of unbalance correction masses are selectable) |

|

| No. of stored work data | 50 data (No limitation when use with USB memory) | |

| Data transfer | Measured data can be transferred to PC or stored USB memory -optional | |

| Others | Power supply | 3-phase AC200V 50/60Hz | Dimensions | 950(W) × 550(L) × 1,200(H)mm |

| Mass | Approx. 200kg | |

| Option | Dynamic response evaluation with non-contact displacement sensor (Lissajous waveform) | |