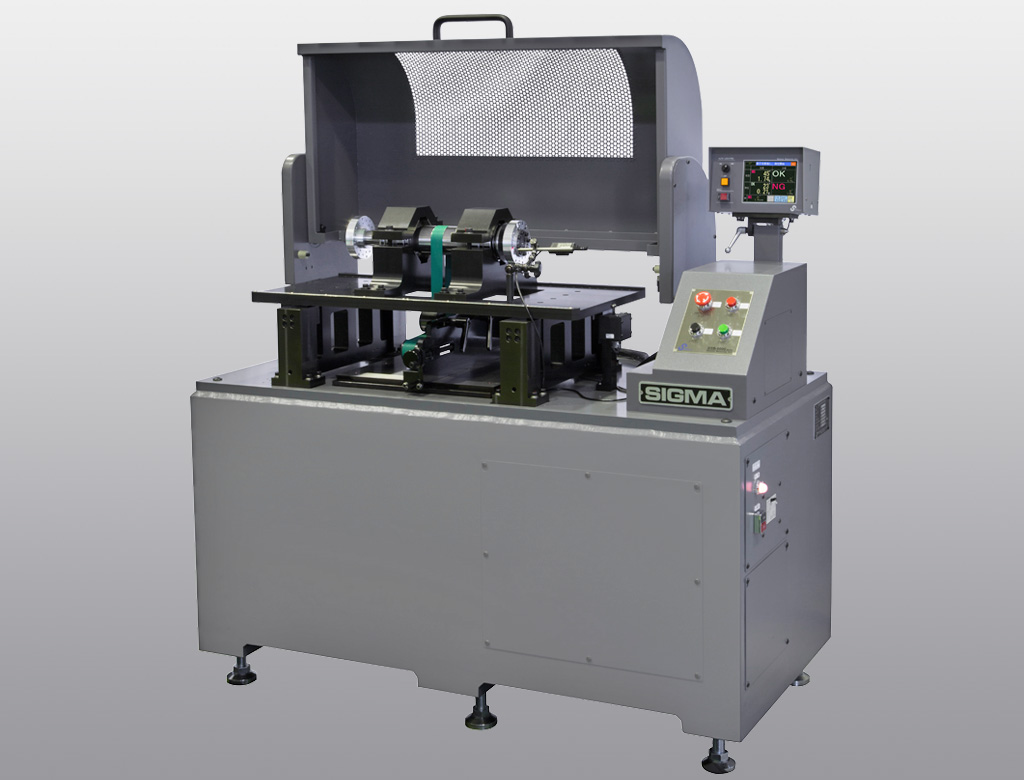

Horizontal 1 to 2 plane Balancing Machine

SSB-6080A

Shaft center axis is fixed by own bearings, high-precision balancing can be performed.

- Balancing plane : 1 and 2

- Workpiece Mass : 80kg max.

- Rotor dia.: ø195mm max.

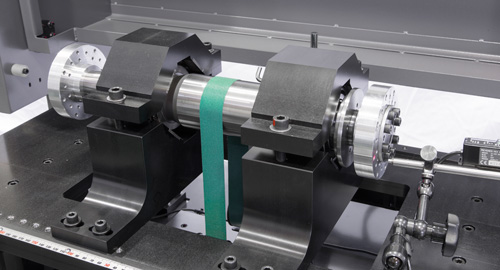

- Belt drive dia.: ø20 to 125mm

- Span across Bearings :160 to 720mm

- Belt drive system :Underslung

- Min. Achievable Unbalance :depend on rotational speed

Rotor shafts of spindle, Turbine rotors of jet engine, etc.

Specifications: SSB-6030AL

| Model | SSB-6080A | |

|---|---|---|

| Workpiece | Max. Mass | 80k g |

| Max. rotor diameter | ø195mm | |

| Diameter for belt drive | ø20 to ø125mm | |

| Span across Bearings | 160 to 720mm | |

| Mechanical unit | Belt drive system | Underslung |

| Motor | AC servo motor, 750W | |

| Balancing speed | 500 to 3,000min-1 (Depending on outer diameter of workpiece) | |

| Bearing support system | Soft type | |

| Angle of unbalance index | Automatic indexing | |

| Between bearings method | Roller bearing and/or V block bearing | |

| Measuring unit | Min. Achievable Unbalance | Depend on rotating speed of workpiece |

| Balancing plane | 1 and 2 | |

| Graphic display | 5.7" TFT color LCD with touch screen | |

| Min. unbalance indication | 0.01mg | |

| Indication mode | Polar coordinates and (3 to 99) components of unbalance vector (add or remove of unbalance correction masses are selectable) |

|

| No. of stored work data | 50 data (No limitation when use with USB memory) | |

| Judgment of measured result | Judgment with set limit value | |

| Data transfer | Measured data can be transferred to PC or stored USB memory -optional | |

| Others | Power supply | 3-phase AC200V 50/60Hz | Dimensions | 1,320(W) × 670(L) × 1,231(H)mm |

| Mass | Approx. 920kg (Including cover and base frame) | |